WE ARE G MACHINE

Headquartered in Portland, Oregon, G Machine Company carries several decades of combined experience in sawmill machinery and optimizer systems design and implementation in the lumber manufacturing industry.

The experience available to you through G Machine Company represents the culmination of generations of circle sawing technology in board edgers and gang saws. We have experience in all aspects of large scale sawing of raw lumber and manufactured wood products.

Whether you are seeking a simple upgrade, an innovative retrofit, or pursuing a turnkey solution to meet your increasing production demands, G Machine Company is here to ensure your system brings you maximum benefits with long-term reliability and low maintenance costs.

“Increasing your profitability is our main goal. Higher throughput, improved quality, higher recovery, and reduced downtime are all the ways a G machine in your sawmill can add up to increased profits.”

tell us about your project

G Machine Company is privileged to speak with you about your next project. We welcome the opportunity to discuss how G Machine Company can help make your project a success.

We also welcome the opportunity to get to know you. We enjoy getting to know our fellow sawmill professionals.

Please drop us a line or give us a call. Introduce yourself and your company. Tell us your project goals. We'll tell you how G Machine Company can help you achieve those goals.

WHAT WE DO

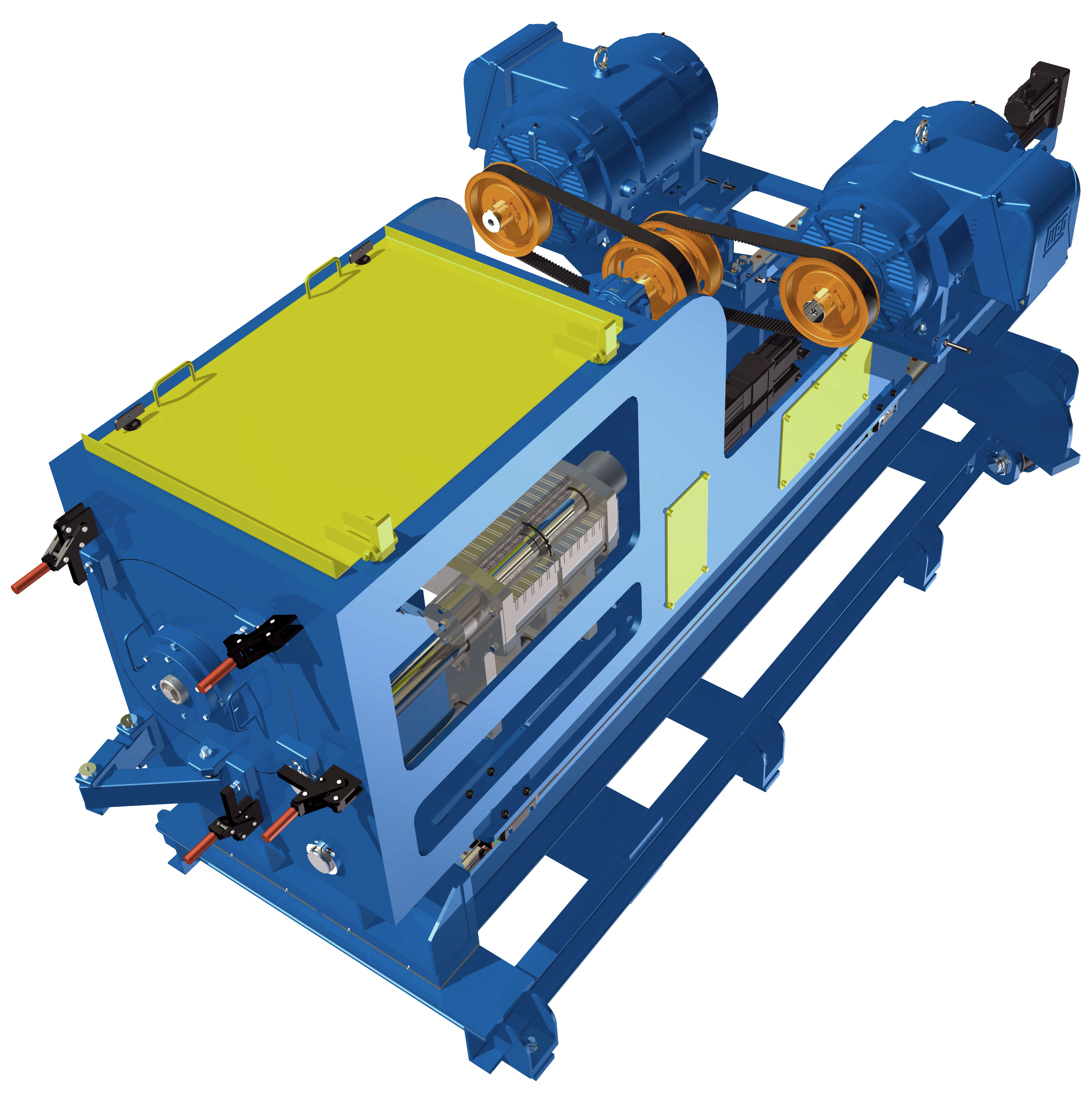

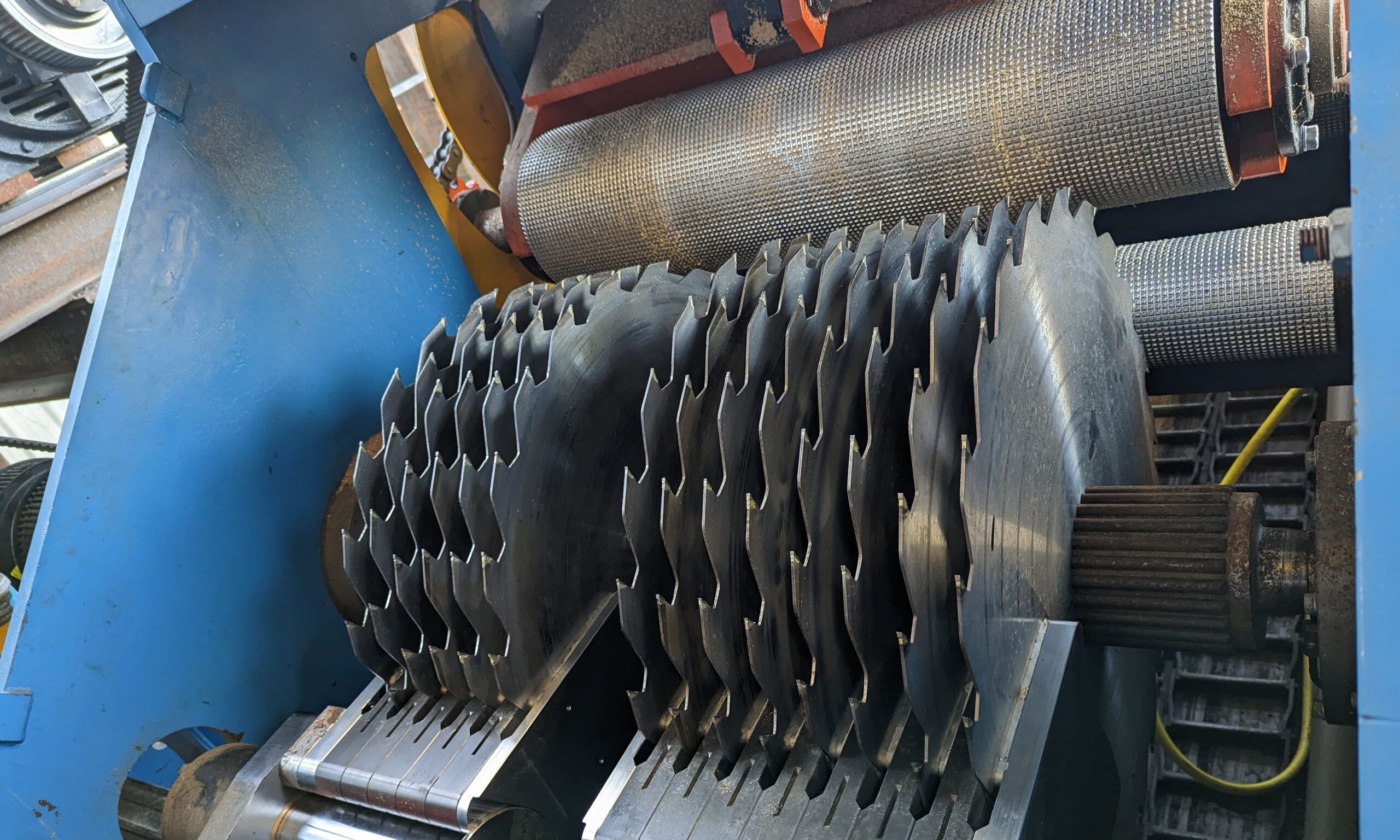

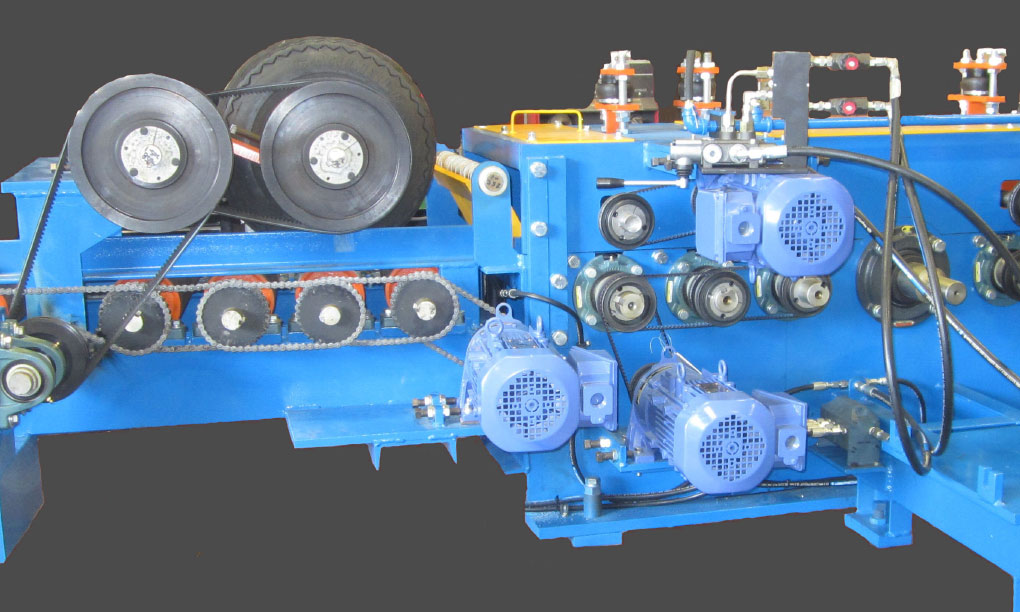

GANG SAWING SYSTEMS

Gang sawing systems come in all shapes and sizes and we build a G Machine to fit your needs. The G Machine Company has the design expertise to bring you fixed saw machines to highly complex combination machines with shifting clusters, conical or drum style chippers, and combination edge/gang machines. Cant sawing for maximum recovery by tracking the saws to follow the sweeps and curves of your raw live edged center cants is right up our alley. If you have a gang sawing requirement, we can build a gang system to handle it.

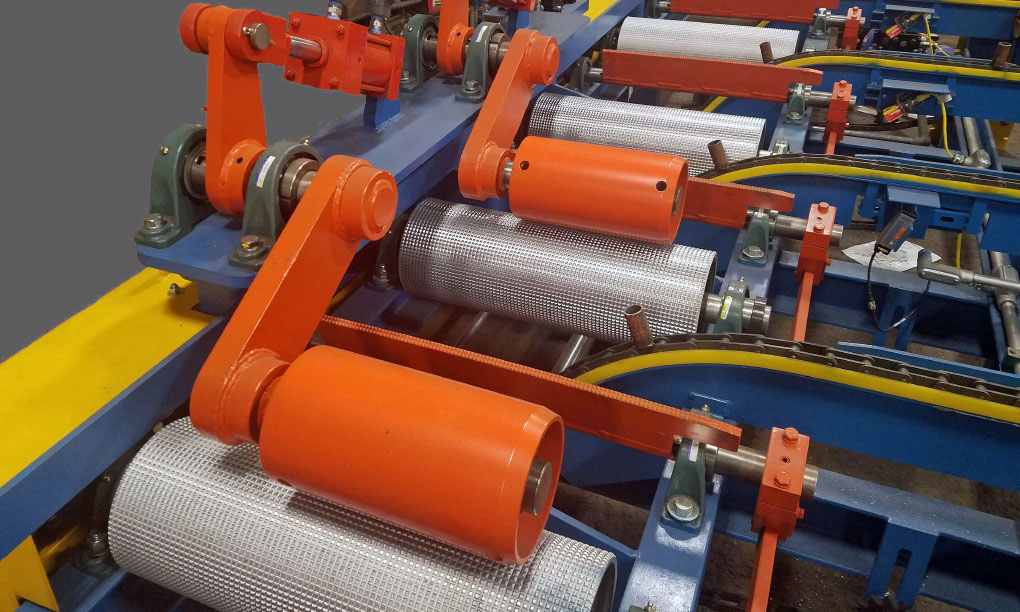

BOARD EDGER SYSTEMS

Regardless of whether you are looking for a simple 2 saw machine or a custom design with multiple saws and a reducer top head to handle jacket boards, a G Mahine will meet your requirements. Thin Kerf sawing and "slew and skew" linear feed systems are our bread and butter. Our machine designs support feed rates to 1500'/min and beyond to get the highest production rates and fastest ROI in the industry.

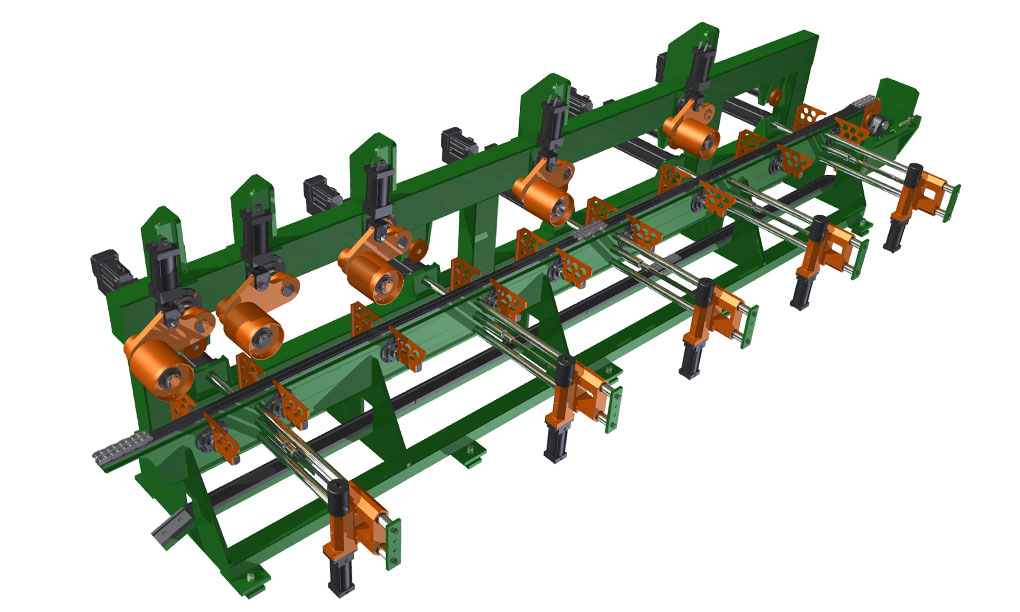

CUSTOM LINEAR & TRANSVERSE FEED SYSTEMS

It doesn't matter to us if you are installing a new machine or retrofitting an existing machine, one thing we know for sure is that no two sawmills are the same. And that means that each application requires a specialized approach to getting your raw materials to and from the machine centers within the constraints imposed by existing machinery layouts or physical room at the facility itself. We build the material handling and feed systems required by the application.

OPTIMIZATION TO ACHIEVE THE HIGHEST ROI AVAILABLE

At the G Machine Company, we focus on what we do best, designing and manufacturing the most advanced sawing machines available to deliver sawing systems to our customers that reach the highest levels of performance. To achieve that goal, we partner with the most qualified specialists in the scanning,optimization and machine control fields to complement our machines and to bring you the combined results of working with specialists providing transverse, and lineal scanning technologies.

UPGRADES, PARTS & SERVICE

When you need to extend the life of your existing machinery, we are uniquely qualified to re-engineer your sawguide system for thin kerf sawing and higher production speeds. We can supply parts and qualified machinery service personnel to assist in edger and gang upgrades of all types to extend the life of your machinery until you are ready to install replacement machines in your mill.

SAWING SYSTEMS ENGINEERING & LAYOUT SERVICES

When you are just not sure how to get your vision integrated into your plant material flow or building constraints, the G Machine Company can help you engineer machinery layouts, plan views and elevations, trash system modifications and just about any other aspect of designing or re-designing your production facility to get the changes you know you need integrated into your existing operations.

PALLET EDGERS

Our G Machine pallet edgers set the standard for combining the rugged reliability of a sawmill duty edger with the simplified requirements of sawing pallet boards. We can provide a high reliability and cost effective solution to your pallet production needs

EMPLOYMENT

We are always looking for the right people

Our continued growth demands we hire the most talented team members we can find to help us meet the demands on our business.

We are always interested in meeting qualified people looking for an opportunity in the fields of Sawmill Equipment Design and Sawmill Equipment Sales.

We are a small firm so we strive to find those individuals who bring a high skill level and great work ethic to our team. If you are focused on high quality, possess a flexible attitude, and are a team player, we want to talk to you.